Simplified

Supply Chain

Packaging, Tools, Secondary Processing, and Assembly — tailored through a single window of contact. We engineer cohesion from concept to unboxing.

Chromatic Unity

The Industry Pain Point

Different substrates absorb pigments differently. Sourcing plastic caps, glass bottles, and wooden brushes from separate factories inevitably leads to fragmented brand aesthetics and noticeable shade deviations.

Our Solution

We utilize spectral data to calibrate pigments across plastic, metal, wood, and fiber simultaneously. One laboratory, one standard—guaranteeing Visual Identity Integrity across your entire product line.

Turnkey

Filling & Assembly Management

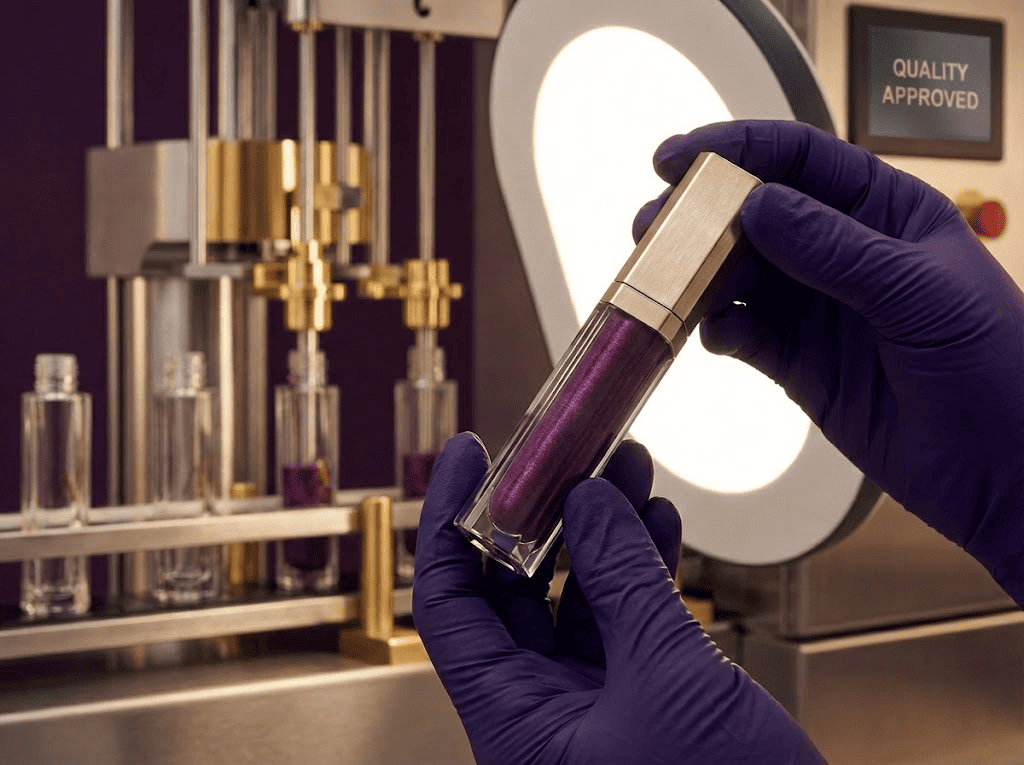

We streamline your production by bridging the gap between packaging and formulation. Through our network of audited, GMP-certified partners, we oversee the filling, sealing, and final assembly processes—ensuring you deal with one entity for the entire project.

GMPC/ISO Compliance

We strictly select production lines that meet ISO 22716 standards, ensuring your products are processed in clinical-grade clean rooms.

Scalable Production

From boutique pilot runs to mass-market volumes. We allocate your project to the most suitable facility based on viscosity and order size.

On-Site Supervision

Our QC engineers monitor the assembly and kitting process on-site, guaranteeing zero-defect delivery before shipping.

Decoration Matrix

A complete library of surface finishes executed in our internal facilities.

No outsourcing, no delays, total quality control.

Silk Screen

Sharp, opaque graphics.

Hot Stamping

Luxury metallic shine.

3D Printing

Tactile relief textures.

Water Transfer

Seamless curve wrapping.

Laser Engraving

Precision permanent etching.

Concept-to-Doorstep Execution

We bridge the gap between product development and global delivery.

One unified workflow for engineering, assembly, and logistics.

Systemic Synergy Strategy

Cross-Material Calibration

We use spectral analysis to ensure Visual Identity Integrity across disparate substrates (Plastic vs. Glass vs. Metal).

Application Engineering

We adjust brush bristle density based on formula viscosity. Perfect pickup, perfect payoff.

Global Delivery Assurance

One Partner, Total Solution

Why juggle five vendors when you can trust one? We unify molding, decoration, and assembly for absolute quality control.