Form Follows

Function

Turn your sketches into shelf-ready icons. Our precision tooling and rapid prototyping reduce development cycles by 40%, ensuring your custom packaging launches faster and fits perfectly.

Development Timeline

Concept & DFM

48 Hours

ID sketching combined with preliminary DFM analysis to ensure mass-production feasibility.

Rapid Prototyping

3-5 Days

SLA/SLS rapid prototyping to verify ergonomics, volume, and assembly fit.

Precision Tooling

35 Days

CNC machining of S136/NAK80 steel cores. High-speed tooling for rapid launch.

T1 Sample Delivery

Day 40

First off-tool samples dispatched for surface finish and dimension approval.

Precision Mold

Engineering

Built for millions of cycles. We engineer precision molds using certified European and Japanese steel grades (e.g., S136, NAK80) to guarantee flawless surface finish and long-term production stability.

Your IP is Secure (NDA)

We sign legally binding NDAs before any discussion. Your proprietary designs and custom molds are your exclusive assets, strictly protected within our facility.

Guaranteed Mold Life

Molds engineered for 500k to 1M+ shots. We match steel hardness to your volume, ensuring the lowest total cost of ownership.

High-Volume Scalability

Optimized 4, 8, 16+ cavity tools with balanced runner systems to maximize daily output and slash unit costs.

2K / Bi-Injection Molding

Combine rigid (ABS/PP) and soft-touch materials (TPE/TPU) in a single cycle for premium, seamless product designs.

Premium Textures & Finishes

From SPI-A1 mirror polish to complex VDI spark erosion patterns and In-Mold Decoration (IMD) for superior tactile quality.

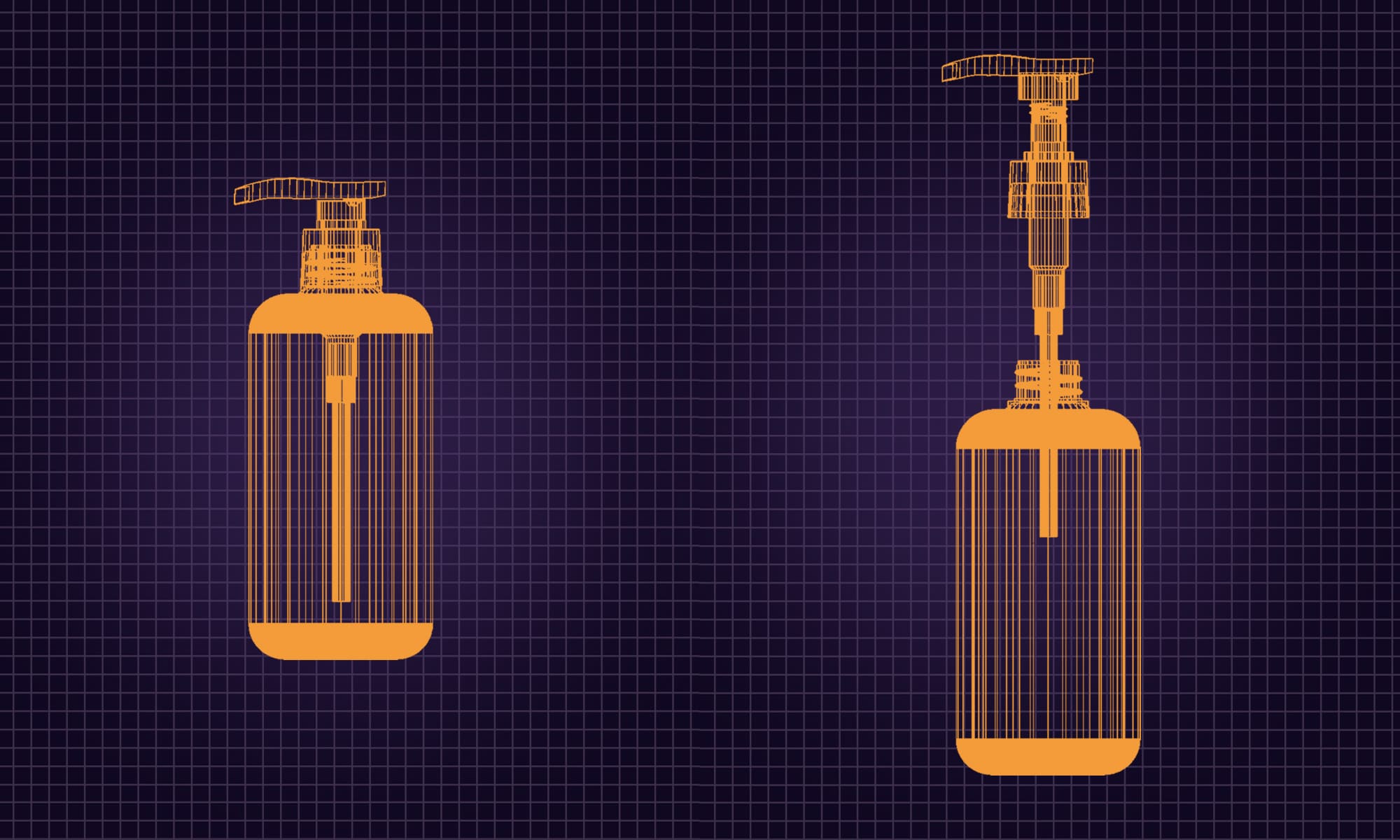

Concept vs. Reality

Precision engineering means no surprises. Drag the slider to compare the initial 3D rendering with the final injection/blowing molded product.

Have a Sketch?

Let's turn your concept into a production-ready reality. Our engineers are ready to review your ID design or 3D files.

Typical Response Time: 12 Hours